TM 11-840-281-35/1

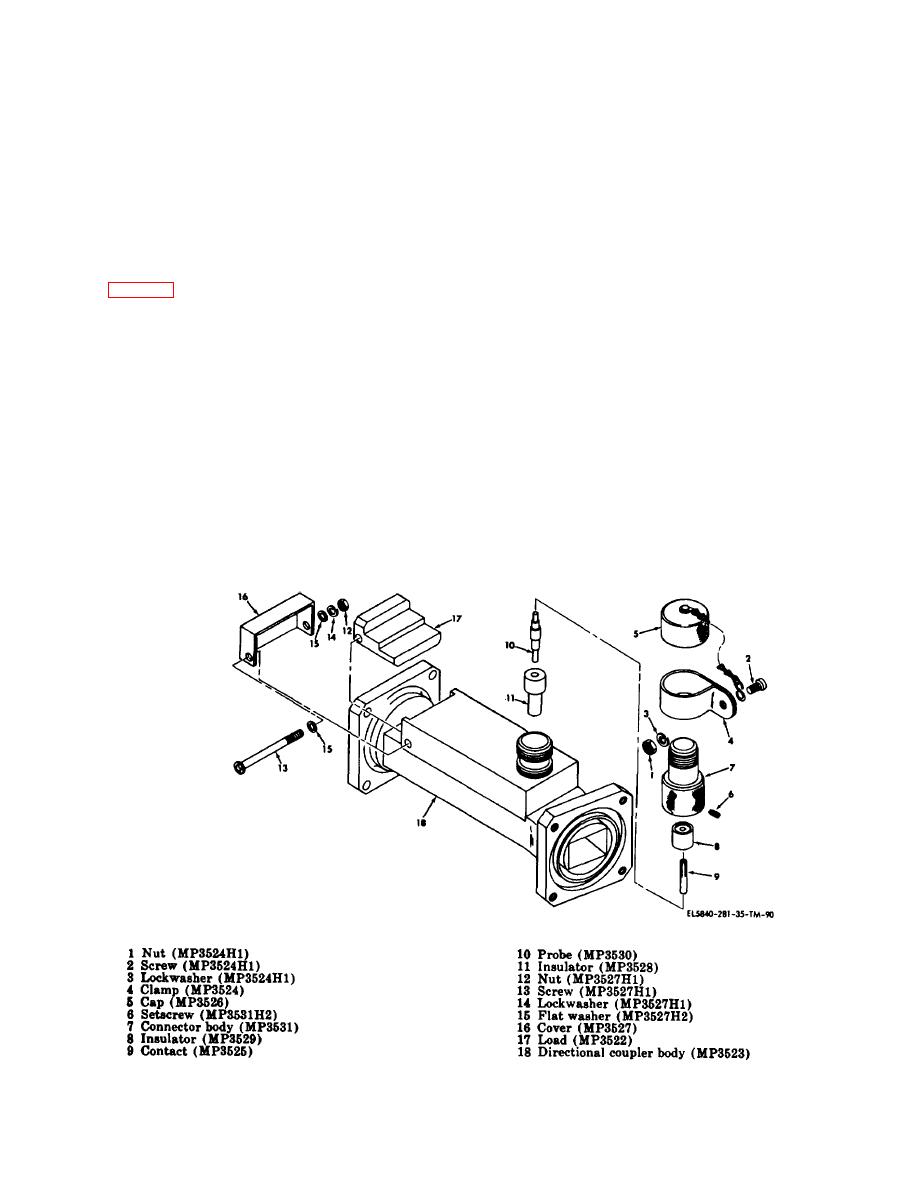

(5) Remove nut (12), screw (13), lockwasher

NOTE

(14), and two flat washers (15).

Shims (6) should be added or removed

(6) Remove cover (16) and load (17) from

to provide minimum end play without

directional coupler body (18).

binding.

b. Assembly. To assemble directional coupler,

proceed as follows:

(6) Secure preformed packings (1) to elevation

rotary coupler to prevent loss until installed on

operational radar set.

NOTE

Cover (16) is to be cemented to

directional coupler body and the

5-23.

Disassembly and Assembly of Directional

attaching hardware encapsulated with a

Coupler

rigid-ratio mixture of Resiweld no. 7004

or equivalent after installation.

a. Disassembly. To disassemble directional coupler,

(1) Install load (17) and cover (16) on directional

proceed as follows:

coupler body (18) using nut (12), screw (13), lockwasher

(1) Remove nut (1), screw (2), lockwasher (8)

(14), and two flat washers (15).

and clamp (4).

(2) Install insulator (11) in directional coupler

(2) Remove cap (5).

body (18).

(3) Remove two setscrews (6) and unscrew

(3) If contact (9) and probe (10) are separated,

connector body (7).

solder together before installing in directional coupler

(4) Remove insulator (8), contact (9), probe (10),

body (18).

and insulator (11).

(4) Install insulator (8) with deepest counter-bore

toward

insulator

(11)

and

screw

connec-

NOTE

Contact (9) and probe (10) are soldered

together, unsolder only if one requires

replacement.

Figure 5-19. Directional coupler, exploded view.

5-60

Previous Page

Previous Page