TM 11-5840-360-14-1-1

5.12.2.13 Lamps

5. Reconnect the harness connector P101 to the

power supply assembly 4/5A1.

1. Remove power per paragraph 5.12.2.

6. Reconnect the Anode lead to the CRT and the

Focus lead to the power supply assembly 4/5A1.

2. Remove all lamps by turning the retaining

7. Mechanically isolate the power supply chassis

spring to the side.

from the Indicator cabinet by placing a clean folded-up

3. Remove all lamps by pulling them out of their

cloth between them.

socket holders.

8. Electrically ground the power supply chassis to

4. Reinstall using the reverse of above.

the indicator cabinet with a clip lead.

9. Verify that all PCBs (including the extender

5.12.3 Alignment Procedures

card) are inserted in their proper locations in the A2

Card Basket.

provide instructions for alignment of all shipboard

10. Set the Indicator POWER switch to TX ON.

adjustable maintenance controls contained in Azimuth

11. Connect an oscilloscope to the collector of

Range Indicators IP-1282 and IP-1283.

When

A1A2Q103.

performed in the sequence indicated, these instructions

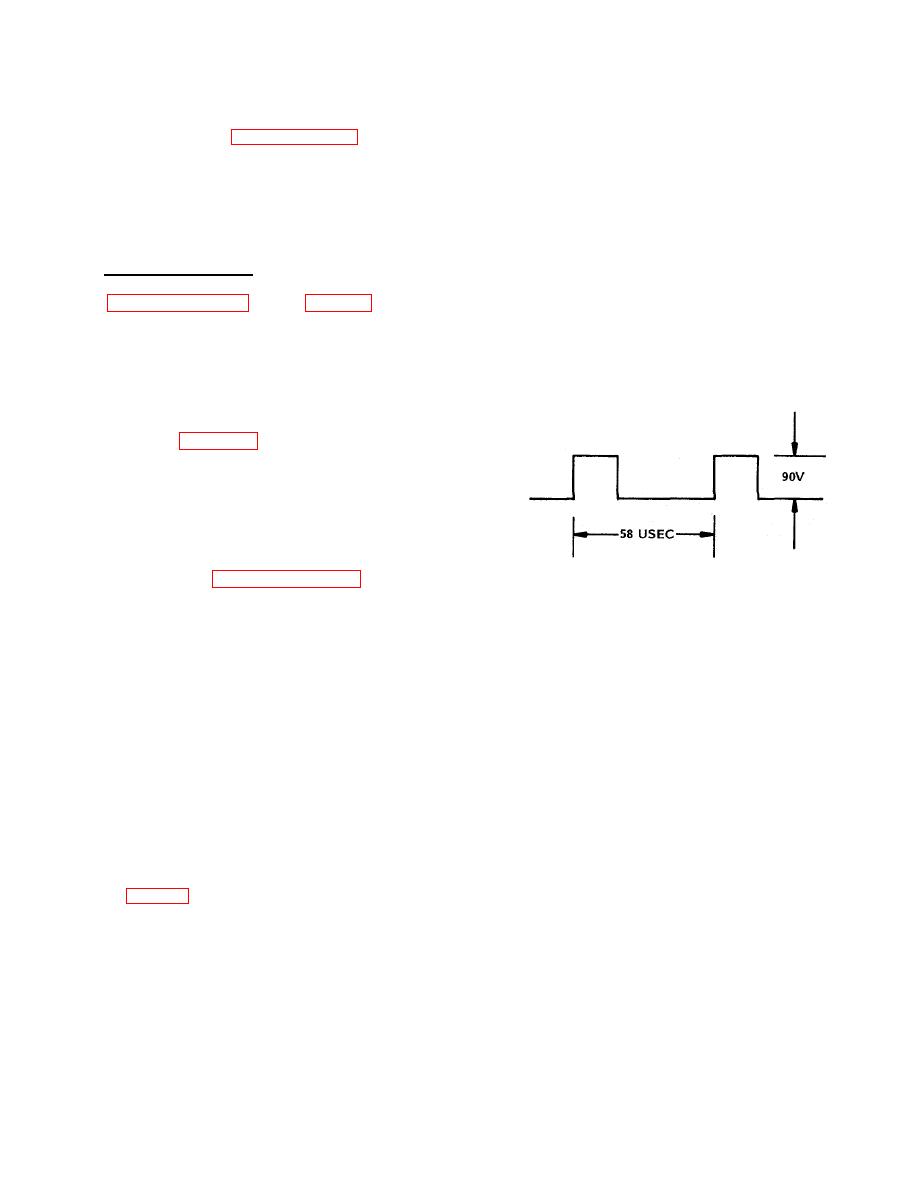

12. Adjust the FREQ-SET control A1A1R47 to

constitute an overall Indicator alignment procedure. The

obtain the waveform shown below:

alignments should be checked and adjusted as

necessary following all Indicator repair and replacement

activities. Refer to Figure 5-7 for location of assemblies

and major components.

5.12.3.1 Power Supply Adjustments, - This procedure

provides instructions for adjustments of power supply

operating frequency, output voltage level, CRT coarse

brilliance and CRT focus. Adjustment of the power

supply overvoltage/overcurrent (OVP/OCP) protection

circuit is covered in paragraph 5.12.3.2 following.

13. Connect a multimeter, set at 10 Vdc scale,

Perform the following steps in the sequence given.

between pin 5 (positive lead) of the extender card and

chassis.

NOTE:

14. Adjust OUTP ADJ control A1A1R28 for a

Power Supply A1 contains two

reading of +5.1 Vdc on multimeter.

controls which are factory set and

15. Disconnect multimeter.

Set SERVICE/

should not be adjusted in the field;

OPERATE switch A1A2S101 to OPERATE.

these are:

WARNING

a. High voltage control A1A3R205.

HIGH VOLTAGE IS PRESENT.

b. PULSE WIDTH ADJ control A1A1R33.

16. Turn front panel BRILLIANCE control fully

1. Set the Indicator POWER switch to OFF.

clockwise.

Adjust BRILLIANCE PRESET control

2. Remove the access cover from the front of the

(A1A2R112) until sweep is barely visible on CRT

Indicator.

display. Adjust front panel BRILLIANCE control for

3. Carefully disengage the A1 High Voltage Power

desired sweep intensity. Adjust GAIN and CONTRAST

Supply from the Indicator cabinet by removing three

fully CCW.

screws per 5.12.2.1.

17. Adjust front panel RANGE RINGS control for

WARNING

desired range ring brightness. Adjust FOCUS control

SET

THE

SERVICE/OPERATE

(R111 on Potentiometer PCB A1A4) to obtain the

SWITCH A2S101 TO SERVICE TO

sharpest possible definition of the range rings on the

DISABLE THE HIGH VOLTAGE

CRT display.

OUTPUT OF THE POWER SUPPLY.

18. Set Indicator POWER switch to OFF.

19. Remove the grounding clip lead and the

4. Position the power supply for easy access to the

protective cloth, and carefully Install the A1 High

screwdriver adjustment potentiometers on the back and

Voltage Power Supply into the Indicator cabinet.

to transistors A12Q101 through Q104 on the side.

5-56

Previous Page

Previous Page