TM 11-5841-287-30

decomposition are toxic and irritating. Since

other loose material from inside the equipment using a

TRICHLOROTRIFLUOROETHANE

shop vacuum cleaner or soft bristle brush

dissolves natural oils, prolonged contact

3-23. Repainting and Refinishing

with skin should be avoided. When

The extent of repainting and refinishing is limited to

necessary, use gloves which the solvent

filling-in scratched or chipped surfaces on the encoder

cannot penetrate. If the solvent is taken

and data lhnk control Prior to painting, the damaged area

internally,

consult

a

physician

should be thoroughly cleaned (para 3-22). Paint should

immediately

be applied evenly with an artists brush Where bare metal

Cleaning of the encoder and data link control is limited to

is exposed, a primer coat should be applied first Light

removal of surface stains and dust accumulations.

sanding may also be performed to smooth edges around

Remove surface stains using a lint-free cloth moistened

the damaged area, as necessary The materials required

with

TRICHLOROTRIFLUOROETHANE

cleaning

for repainting and refinishing are listed m paragraph 3-5.

compound.

After

cleaning

with

TRICOLOR

Refer to TB 43-0118 for detailed instructions on

TRIFLUOROETHANE, dry the area thoroughly with low

repainting and refinishing electronic equipment

pressure, filtered compressed air. Remove dust and

Section V. DIRECT SUPPORT TESTING PROCEDURES

3-24. General

WARNING

This section contains procedures for physically testing

Disconnect power from the equipment before

the encoder and data link control. Functional tests for

performing physical inspection procedures.

the encoder circuit cards are also presented. Refer to

Failure to comply could result in electrical shock

TM 11-5841-286-13 for inspection and testing of Radio

injury to personnel.

Set AN/ARC-164(V)16.

the encoder and data link control.

The physical

inspection procedures are to be accomplished before the

3-25.

Physical Inspection

encoder circuit card tests (para 3-26).

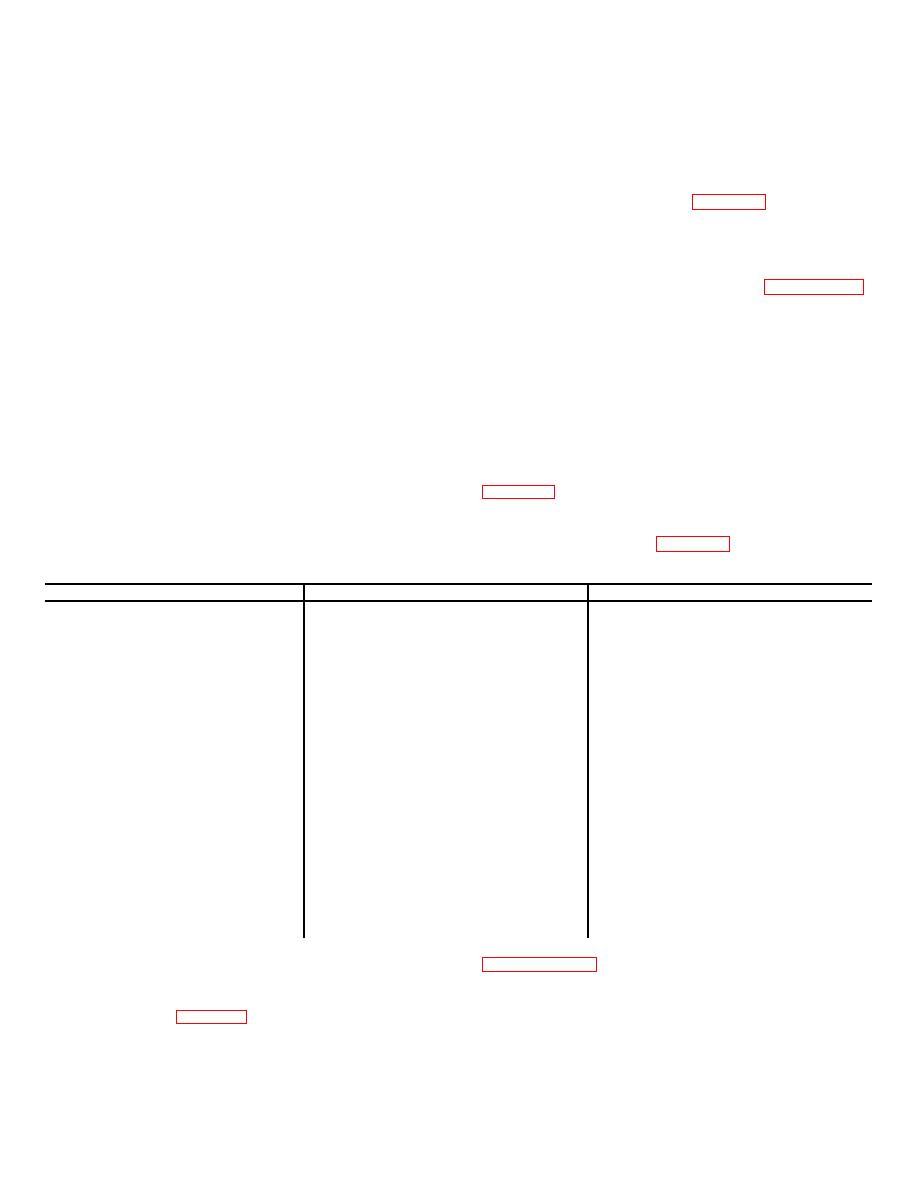

Table 3-3. Physical inspection Procedure

Item to be Inspected

Procedure

Standard

All exterior surfaces

Check for stains, fungus and corrosion

Surfaces shall be free of stains, fungus and

corrosion

Chassis

Check for dents, cracks and general

Chassis shall be free of structural damage

structural damage

Painted surfaces.

Check for scratches and cracked or peeling

All painted surfaces shall be free of

pint.

scratches which penetrate the pant, and

cracked or peeling pant

Screws, bolts and nuts

. Check for loose or missing screws, bolts

All screws, bolts and nuts shall be tight,

and nuts.

none shall be missing

Front panel switches.

Check for loose or missing knobs and

Switch knobs shall be tight and mechanical

normal switch action

action normal

Front panel indicators.

Check for burned-out or missing bulbs

Indicator bulbs shall be installed and m

working order

Fuses and fuseholders

Check for burned-out or missing fuses

Fuses shall be installed and m working

order

Electrical components

Check for signs of heat damage ( charing

Electrical components shall be free of heat

discoloration)

damage

Connectors

Check for bent, broken or missing pms

All connector pins shall be straight and

undamaged

Wiring

Check for breaks and damaged or frayed

All wiring shall be free of damage to

insulation

insulation and conductors

tested and their referenced paragraphs Refer to

3-26.

Testing Encoder Circuit Cards

a. General. Functional tests for the encoder

replacement procedures If a fault (nogo indication) is

circuit cards are presented in the following paragraphs.

indicated, remove the defective card from the test setup

These go/no-go tests provide positive indication of circuit

and return it to the depot for repair.

card performance. Table 3-4 lists the circuit cards to be

Change 1 3-31

Previous Page

Previous Page