TM 11-5841-287-30

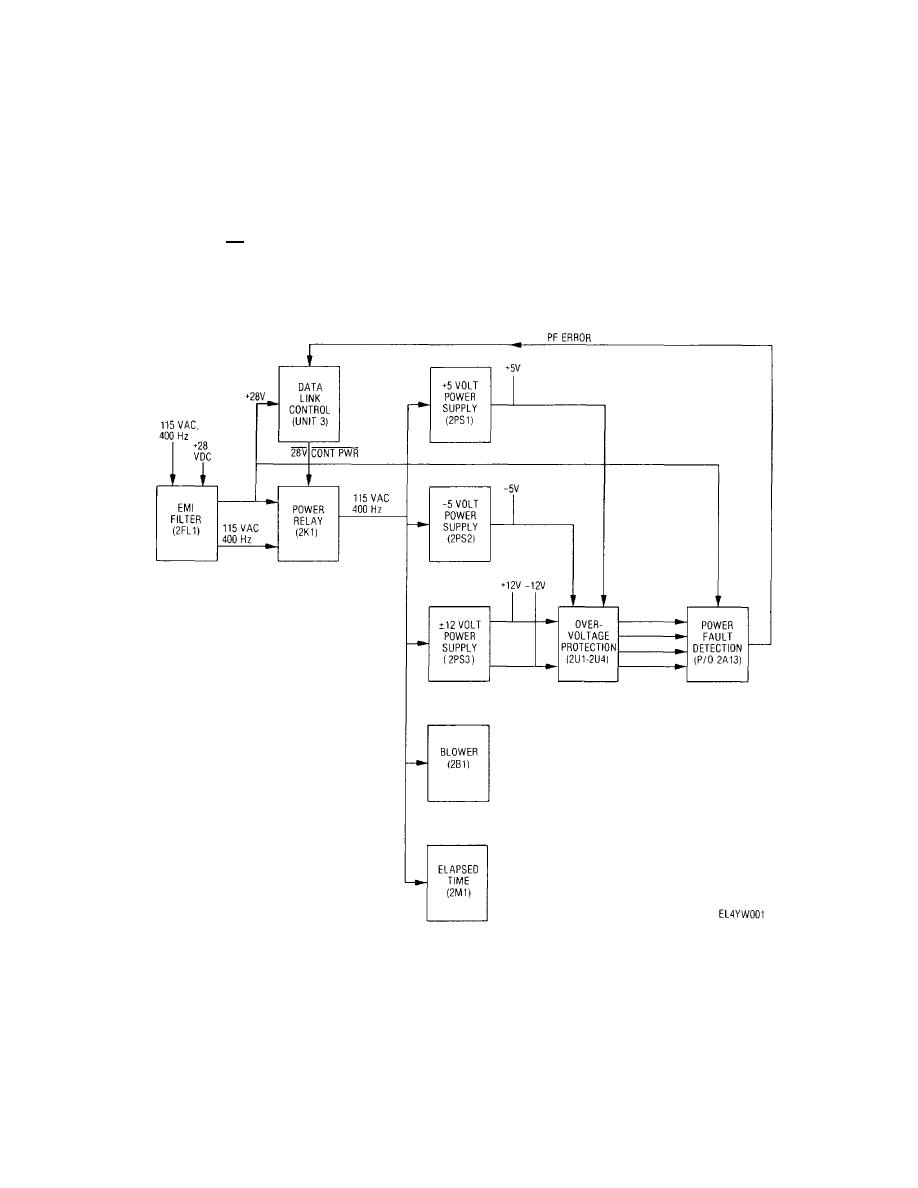

power relay K1 and to power fault detection logic located

potentiometer on each power supply permits nominal

on power fault detector module 2A13 In addition, +28 V

output voltage setting For encoder protection,

is supplied to the data link control for lamp power From

overvoltage sensors are located across each power

FL1, the 115 V ac is applied to contacts of relay K1 Relay

supply output Power supply functional status is

K1 is energized by placing the power switch on the data

monitored continuously In conjunction with operation of

link control in the STBY or XMT position, at which time

the power fault detection logic and ENCODER FAULT

the CONT PWR line goes low With relay K1 energized,

indicator on the data link control As long as the power

115 V ac is then applied to +5 volt power supply PS1, -5

supply voltages remain normal, the PF ERROR line is

volt power supply PS2, + 12 volt power supply PS3,

grounded causing the ENCODER FAULT indicator to

blower B1, and elapsed time meter M1 The power

remain off Should any power supply voltage drop below

supplies furnish regulated operating voltages for the

or rise above normal, the PF ERROR line is sent high by

encoder circuitry, and feature current limiting for overload

the power fault detection logic, illuminating the

protection

An

externally

accessible

ENCODER FAULT indicator

Figure 2-12. Encoding subsystem power supply and distribution block diagram.

2-19

Previous Page

Previous Page