TM 11-5841-287-30

b. Test Setup. The encoder and data link

3-7.

Encoder and Data Link Control

control test setup is shown in figure 3-1. Perform the

Troubleshooting

physical tests given in table 3-3 prior to connecting the

a. Tools and Test Equipment Required. The

equipment in the test setup.

tools and test equipment required for troubleshooting the

encoder and data link control are those in paragraph 3-4.

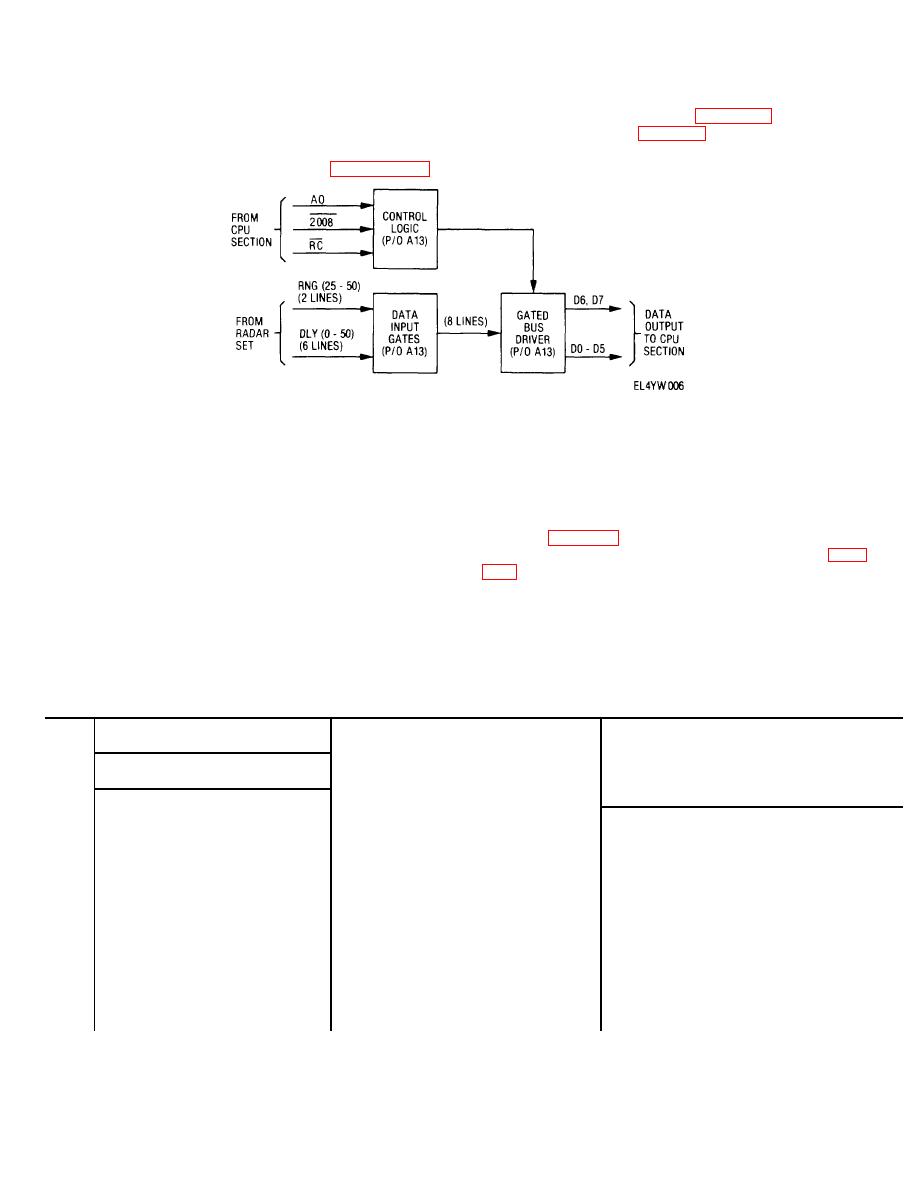

Figure 3-1. Encoder and data link control test setup.

c. Preliminary Control Settings.

d. Testing and Troubleshooting Procedures.

Set the

equipment controls as follows prior to beginning the

The first step in troubleshooting the encoder and data

functional test procedures:

link control is to perform the functional test procedure

given in table 3-1. Then, when a fault indication is

Control

Setting

obtained, locate the appropriate MALFUNCTION in table

Data link control:

INSPECTION and CORRECTIVE ACTION columns of

POWER

OFF

the table. Test the repaired circuit card or replacement

Test Set, Electronic Systems

circuit card or component before installing it in the

TS-3796/UKM-4 (control interface

encoder. Then retest the encoder with the repaired or

unit):

new circuit card or component installed.

POWER

OFF

MODE SELECT

UNIT TEST ENC

Table 3-1. Encoder and Data Link Control/Functional Test

Control settings

Step

Test

Equipment

Performance standard

no,

equipment

under test

a. Observe ENCODER and RT

a. Indicators are off.

Control

POWER switch:

1

Interface

STBY.

FAULT indicators on data link

unit:

control.

b. Observe encoder ELAPSED TIME

b. Blower operates

POWER

c. Observe encoder ELAPSED TIME

c. Meter operates as indicated by small tab

switch:

Meter

pulsating in meter face

ON.

2

AIRBORNE BITE

Observe RT FAULT, ENCODER

RT FAULT and ENCODER FAULT

switch: Press

FAULT, and BITE IN PRCS

indicator lamps illuminate for

down

indicator lamps on the data link

approximately3 seconds. And then go

control

off. BITE IN PRCS indicator lamp stays

illuminated 3 additional seconds and

then go off

Change 1 3-2

Previous Page

Previous Page