TM 11-6625-1831-13

Section III. OPERATOR/CREW MAINTENANCE

2-10.

INTRODUCTION

You must perform Preventive Maintenance Checks and Services (PMCS), and some maintenance procedures on the test

set to keep it operating properly. Use the PMCS chart in paragraph 2-11 to check the test panel indicators before and

during operation. Use the maintenance chart in paragraph 2-12 to replace a defective indicator or lens.

Each chart in this section has an INITIAL SETUP section. This section gives information you need before you start the

procedure.

In this INITIAL SETUP section, resources required are not listed unless they apply to the procedure. Personnel are listed

only if the task requires more than one. If PERSONNEL is not listed, it means one person can do the task. The normal

standard equipment condition to start a maintenance task is with power off EQUIPMENT CONDITION is not listed unless

some other condition is required besides the power being off.

2-11.

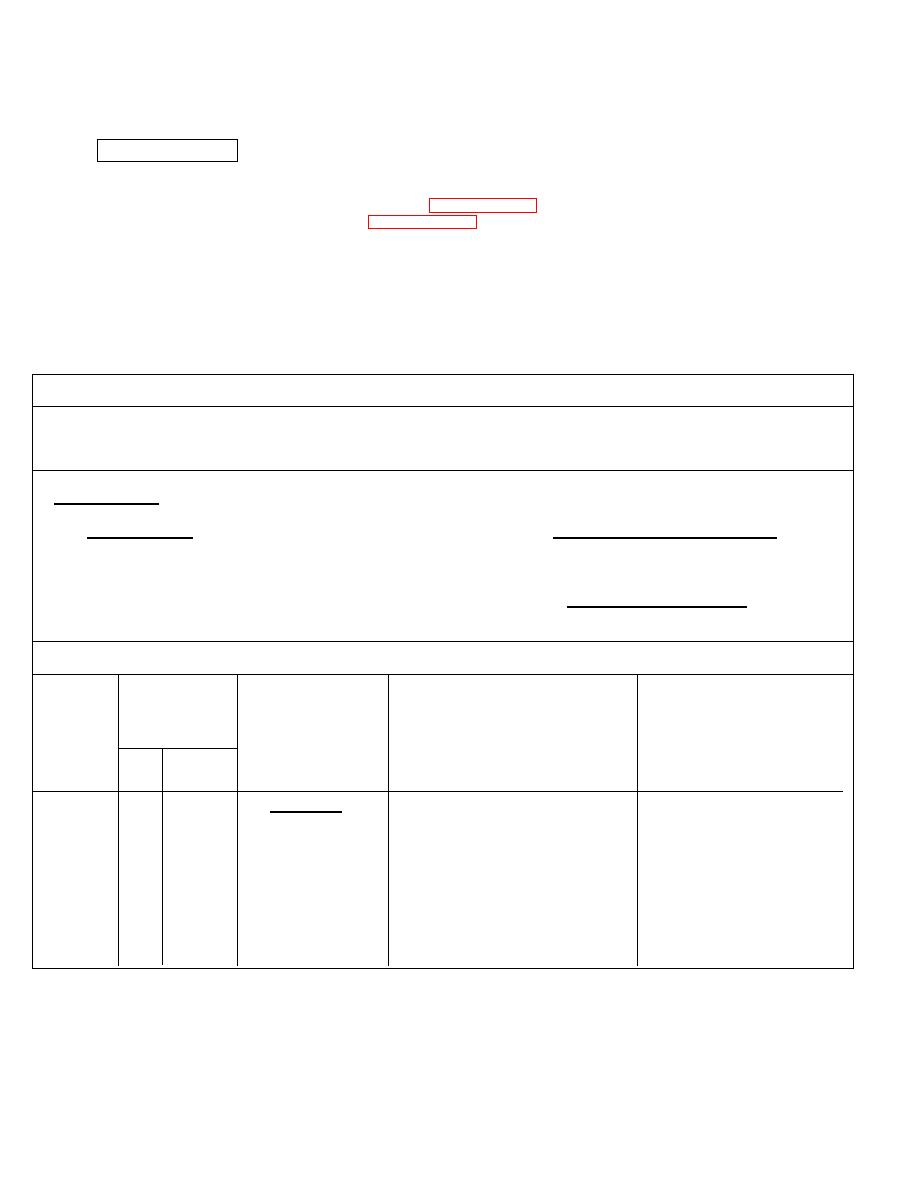

OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

This task covers:

Preventive maintenance procedures

INITIAL SETUP

Test Equipment

Special Environmental Conditions

None

None

General Safety Instructions

None

B = Before use

D = During use

Interval

Procedures

Equipment is

Item

Item to be

Check for and have repaired

Not Ready/

No.

B

D

Inspected

or adjusted as necessary

Available if:

Test Panel

1.

Panel Indicators

Check for loose or cracked

Any lens is cracked

lamp lenses. If loose,

screw lens in until tight.

Panel Indicators

Turn on PANEL LIGHTS TEST

Any indicator does

switch. Check that all

not light

indicators light.

2-11

Previous Page

Previous Page