TM 11-5841-287-12

CHAPTER 3

MAINTENANCE

Section I. OPERATOR/CREW MAINTENANCE INSTRUCTIONS

the CAUTIONS and WARNINGS. Perform your before

3-1. Tools

and

Equipment

Required

for

(B) PMCS.

Operator/Crew Maintenance

(2) While you operate. Always keep in mind

Repair parts, special tools, special test equipment, and

the CAUTIONS and WARNINGS. Perform your during

other special support equipment accessories issued with

(D) PMCS.

or prescribed for use by the operator of the data

(3) After you operate. Be sure to perform

transmitting set are listed in the Components of End Item

your after (A) PMCS

List, Appendix B.

(4) If your equipment fails to operate. Report

3-2. Operator/Crew Lubrication Instructions

any deficiencies using the appropriate forms(TM 38-750)

No lubrication of the equipment is required.

b. PMCS Procedures. Refer to table 3-1 for

3-3. Operator/Crew Preventive Maintenance Checks

operator/crew PMCS procedures.

and Services (PMCS)

a. General.

Observe the following general

precautions when performing the PMCS procedures.

(1) Before you operate. Always keep in mind

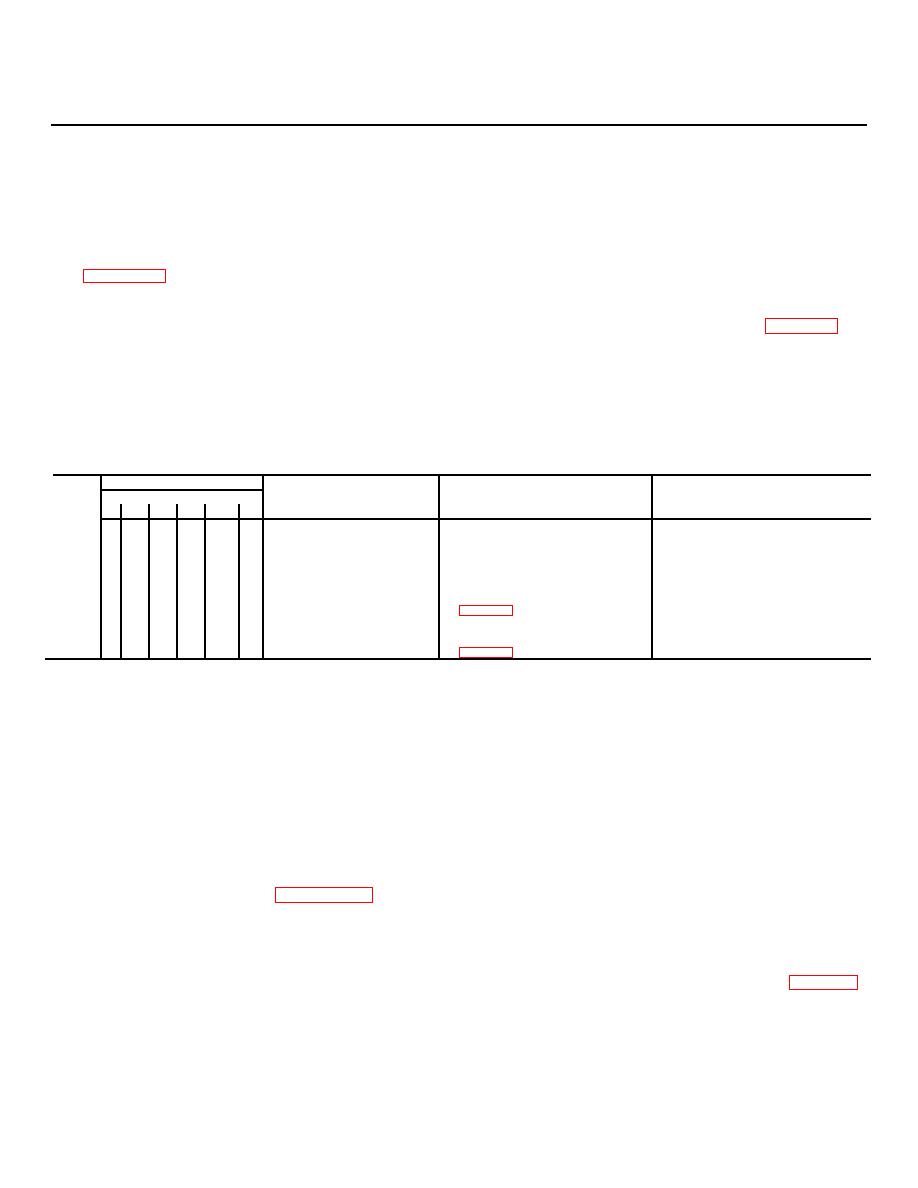

Table 3-1 Operational Crew Preventive Maintenance Checks and Services

B-Before

A--After

M-Monthly

D-During

W-Weekly

C-Combat operability check

Interval

Equipment will be

Item

Item to be

Procedures

reported not ready

No

BD

A

W

M

C

inspected

(Red) If

1

All control knobs

Check all knobs for looseness or

Knobs are missing or controls

binding. Tighten knobs as required

are inoperative

2

All indicator lights

Check all indicators for looseness

Indicators are loose or broken

and broken, damaged, or missing

or missing parts.

parts.

3

Data transmitting set.

Perform preflight (BITE) checks

ENCODER FAULT or R

FAULT indicator remains on

4

data transmitting set

Perform inflight (BITE) checks

ENCODER FAULT or RT

FAULT indicator remains on

No maintenance functions

are

allocated

to

this

3-4. Operator/Crew Troubleshooting

maintenance category

No troubleshooting is required by the operator/crew .

3-5. Operator/Crew Maintenance

Section II. ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

3-6. Tools, Equipment, and Materials Required for

3-8. Organizational Repainting and Refinishing

Organizational Maintenance

Instructions

Tools, equipment, and materials required for

No repainting or refinishing instructions are required at

organizational maintenance are listed below.

the organizational level.

a. Tools. Tool Kit, Electronic Equipment TK-

3-9. Organizational Preventive Maintenance Checks

101/G.

and Services (PMCS)

b. Materials.

Refer to Appendix E for the

a. General

materials used at the organizational maintenance

(1) If your equipment fails to operate. Report

category.

any deficiencies using the appropriate forms(TM 38-

c. Test Equipment.

750).

(1) Auxiliary power unit (APU) capable of

(2) Special PMCS intervals. in addition to the

producing 28 volts dc at 200 amperes.(Refer to aircraft

flying-hour intervals specified in the PMCS (table 3-2),

electronic configuration technical manual).

accomplish the 100-hour checks under the following

(2) Multimeter AN/USM-223

conditions

3-7. Organizational Lubrication Instructions

No lubrication of the equipment is required.

3-1

Previous Page

Previous Page