TM 11-5840-360-14-1-1

5.12.3.4.2 The following steps are applicable to

5. On A6 PCB solder one end of a six-inch jumper

AN/SPS-64(V)2, (V)3 and (V)4 installations only. The

at Delay Select terminal listed for Condition 1 in Table

procedure must be performed for each Indicator

installed.

6. Insert PCB extender card into slot A2A6 of the

NOTE:

Card Basket.

7. Insert the PRF Generator PCB A6 into the

System mode switching is required

extender card.

during this procedure.

When a

8. Set Indicator POWER switches as follows:

procedural step calls for mode

a. Master Indicator(s): TX ON

selection,

refer

to

the

table

b. Slave Indicator(s): ST BY

referenced below for the applicable

9. Set all Indicator RANGE SELECT switches to

system installed.

.25 MILE and adjust for normal display.

10. Visually identify a long straight target such as a

AN/SPS-64(V)2:

pier at a distance between 100 yards and 1/8 mile.

AN/SPS-64(V)3:

11. Locate target identified in step 10 on CRT

AN/SPS-64(V)4:

display of Indicator under test and proceed as follows:

a. If the straight edge of the target is

1. Set all Indicator POWER switches to OFF.

"pulling" (bowed toward the center of the

2. At Indicator A:

display), proceed to step 18.

a. Remove the upper access cover from the

front of the indicator.

b. Remove the vibration bar by first

removing the 2 screws one in the upper

right hand corner. The other screw is in

the lower left hand corner.

c. Remove the PRF Generator PCB A6 from

the A2 Card Basket.

3. Verify that E17 is jumpered to E54 (U23 pin 9)

on A2A6 PCB (install if necessary) .

NOTE:

Steps 4 through 25 following will be

performed with Indicator A defined

as the Indicator under test.

4. At Switching Unit(s), establish a mode in which

Indicator under test and associated receiver transmitter

are selected per Condition 1 of Table 5-4.

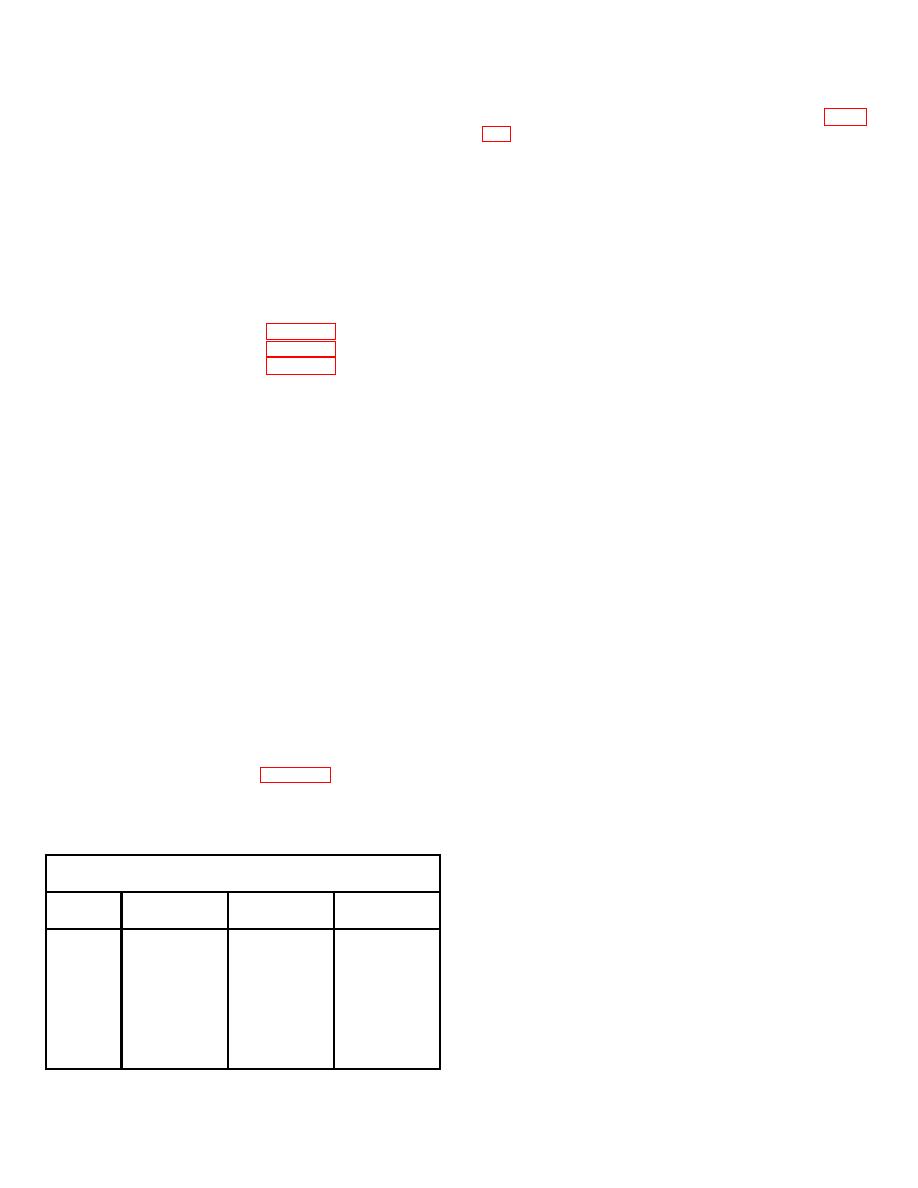

Table 5-4. Multiple Indicator System

Range Zero Alignment Data

MODE

Con-

Indicator

Associated

Delay

dition

Under Test

Rcvr Xmiter

Select

1

MASTER

MTR-I

E35

2

SLAVE

MTR-I

E33

3

MASTER

MTR-II

E34

4

SLAVE

MTR-II

E32

5-59

Previous Page

Previous Page