TM 11-5840-360-14-1-1

condition is not met, perform steps

22. Adjust Y-reference gain control R1 on Position

33 and 34.

Transmission PCB A2A8 to obtain exactly 10 volt peak-

to-peak signal.

33. Loosen CRT yoke clamp and carefully rotate the

23. Connect oscilloscope at pin P of EBL PCB

yoke until sweep origin moves vertically between

A2A9/extender card.

OFFSET switch settings. Tighten the yoke clamp,

24. Adjust X-reference gain control R7 on A2A8

insuring that the yoke does not slip down.

PCB to obtain exactly 10 volt peak-to-peak signal.

34. Repeat steps 28 through 32 above until

25. Observe the range rings, which should now be

requirements of steps 29, 31 and 32 are met

nearly circular but not necessarily centered.

simultaneously.

26. At A2A10 PCB, adjust R61 and R66 controls

35. Set OFFSET switch off. Set Indicator POWER

seven turns clockwise.

switch to OFF.

27. Observe that the octagonal sweep display has

36. Remove EBL PCB A9 and extender card. Insert

increased in size; verify that at least five range rings are

A9 PCB (without extender) into A9 slot of card basket

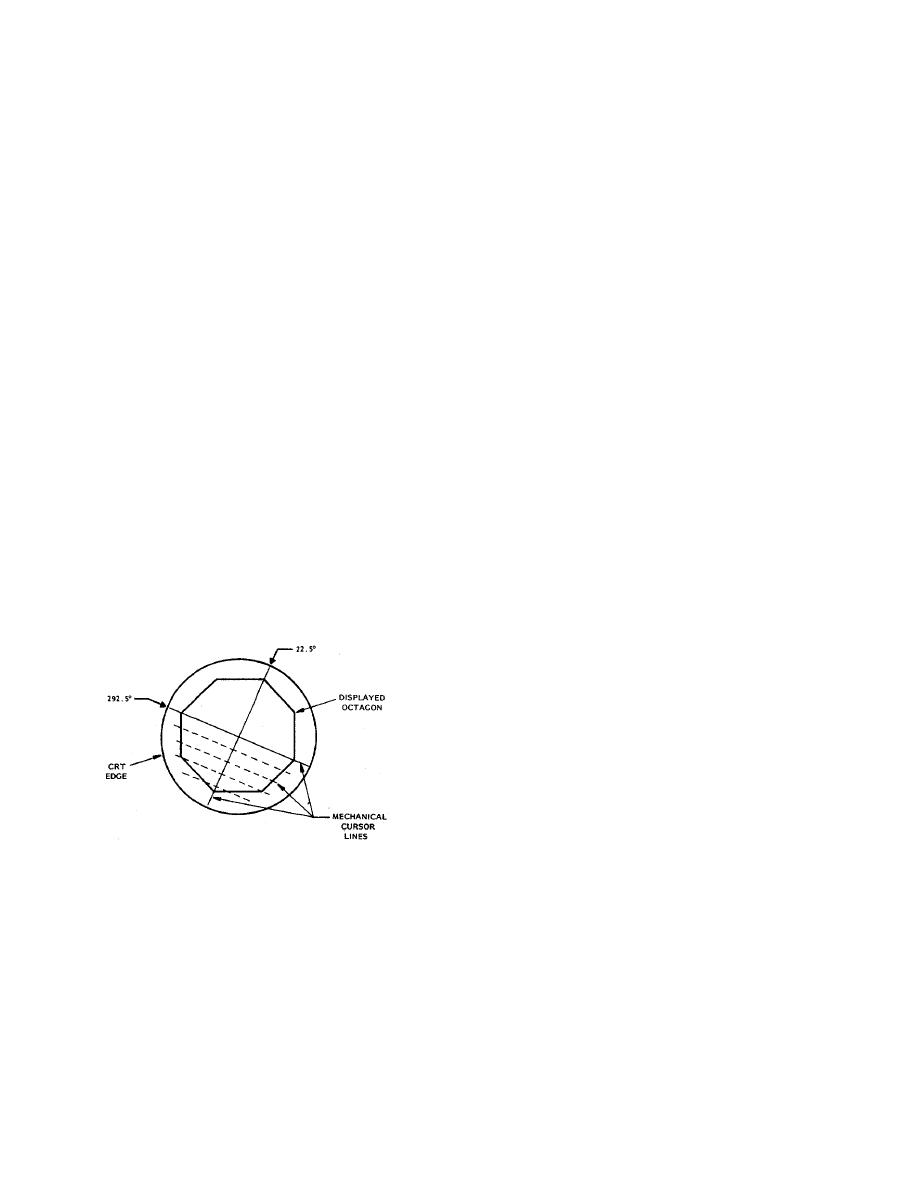

visible.

A2.

28. Adjust CURSOR control to position CRT

37. Remove Sweep Generator PCB A10 from card

mechanical cursor line at exactly 22.5 on relative

basket A2. Mount A10 PCB on extender card and insert

bearing scale.

extender card into A10 slot of card basket.

WARNING

38. Set Indicator POWER switch to ON.

115

VAC

IS

PRESENT

AT

39. Adjust R54 on the A2A10 PCB clockwise until

TERMINALS OF FL1 AND FL2 IN

the sweep just covers the face of the CRT, i.e., just until

VICINITY OF CRT TUBE SOCKET.

the straight sides of the octagon are not visible.

EXERCISE EXTREME CARE TO

40. Adjust R11 on the A2A10 PCB until the range

AVOID CONTACT.

rings are approximately centered on the vertical axis of

the display.

29. Locate the CRT centering magnet adjustment

41. Adjust R31 on the side of A2A10 PCB until the

tabs in the base of the yoke assembly. Carefully adjust

range rings are approximately centered on the

the tabs to position the displayed octagon with respect to

horizontal axis of the display.

the mechanical cursor lines as shown below; insure that

42. Loosen captive screws and raise Indicator bezel

cursor lines intersect octagon internal angles at 22.5

assembly until it locks in position.

and 292.5

.

43. Connect multimeter, set to 5 Vdc scale, between

chassis (negative lead) and +E terminal of EBL

potentiometer R14 (on under side of bezel).

44. Adjust R70 on EBL PCB A2A9 to obtain exactly

+5.0 Vdc reading on multimeter.

45. Connect multimeter between chassis (positive

lead) and -E terminal of R14; verify multimeter reads -

5.0 0.1 Vdc.

46. Set Indicator POWER switch to OFF.

47. Remove A2A10 PCB and extender card. Insert

A10 PCB (without extender) into A10 slot of card basket

30. Adjust CURSOR control to position CRT

A2.

mechanical cursor line at exactly 0 on the relative

48. Mount EBL PCB A9 on extender card; insert

bearing scale. Adjust BRILLIANCE control to define

extender card into A9 slot of card basket A2.

point of sweep origin at center of CRT.

49. Set Indicator POWER switch to ON.

31. Adjust A1R12 and A2R12 on Sweep Output

50. With RANGE SELECT switch at 24 MILES,

assembly A3 to position the CRT sweep origin directly

adjust VRM handwheel to obtain 46600 yards (23 miles)

under the center of the mechanical cursor.

readout on VRM LED indicator at top of CRT. Adjust

32. While setting OFFSET switch alternately on and

VRM intensity control until VRM range ring is visible.

off, verify sweep origin moves vertically on CRT display,

51. Turn EBL front panel knob to position displayed

remaining under the mechanical cursor line for both

EBL at 0on relative bearing scale.

positions of the OFFSET switch.

52. Adjust R1 on Position Transmission PCB A2A8

NOTE:

to superimpose the EBL VRM dot on the VRM range

When the requirement of step 32 is

ring.

met, proceed to step 35. If that

5-62

Previous Page

Previous Page